There is a stationary side stator and a spinning side rotor each with cup shaped pockets that transfer water from one side to the other. The paper investigates the effect of several design parameters of a dynamometer water absorber brake.

Pdf Design Development Of Dynamometer Water Absorber Semantic Scholar

Incorporated into a water brake engine dynamometer.

. Early Superflows did have the open rotor design and are very capable of good results on small engines. With Southern California facing a severe drought Los Angeles residents and businesses will soon be subject to outdoor watering restrictions Mayor. The resistance in each coil is 0945 ohms.

Rename or reorder a page via the settings menu next to the page name. It is no wonder that water brakes are virtually the only choice for testing 2000 horsepower drag car engines. Water absorbent beads Despite that is producing your copy ensure the headline around the front in the brochure is in the form of a matter.

We built a water brake years ago but want to build an electro-magnetic eddy current design that is more mobile and compact. Such applications include the bench testing of motorcycle automotive. Toroidal-flow absorbers couple to engine either via the docking-stations telescoping driveshaft or the mobile-stands heat-treated 1-38x10-spline input shaft and your clutch disk or heavy-duty dampened drive plate.

The DYNOmites integral torque arm fully captures this parasitic drag so these do not represent un-measured power losses. A popular alternative to eddy brakes is the water brake in particular for those. Absorber capacities are RPM dependent.

Alternatively click a pages name to rename it or drag a pages name to reorder it. Invented by British engineer William Froude in 1877 in response to a request by the Admiralty to produce a machine capable of absorbing and measuring the power of large naval engines water brake absorbers are relatively common today. Brake caliper on a bearing with a load sensing scale.

If the brake gets too hot mist it with water. The water brake absorber is sometimes mistakenly called a hydraulic dynamometer. When water is introduced into the absorber.

The existing system uses two individual absorbers. Water Brake Engine Dynamometers - 35X-Series 7350506 35X06 Water Brake Engine Dynamometer Shown Overview Power Test 35X-Series Water Brake Dynamometers are. For trucking off-road military and mining equipment Taylor Dynamometers water brake dynamometers also known as hydraulic dynos offer the rugged operation and accuracy you need to ensure success.

There is a good paper titled Design development of Dynomometer water absorber by Karlis Banis. The shock caused by the acceleration of the wat. We have been shopping for a year trying to snag some used ones.

By comparison a 300 pound air-cooled eddy-current absorber with the same continuous power rating is only good to 7000 rpm. Pre-machined mounting plates fit popular GMFord bell-housing patterns may be custom drilled. A 4-minute how-it-works video tutorial explaining how engine-dynamometer water-brake absorbers work.

As the turbine or propeller turns mechanical energy is transferred to the water due to turbulence and friction. To complete the water dynamometer a control system. They are noted for their high power capability small.

This type of absorber is widely used in dynamometer testing of various applications due to its relatively inexpensive and power-dense design. Most all designs out there are using either the Klam or Telma power absorbers for truck drive lines. Hydraulic application via hose means little external influence on the torque reading.

For example our 5 absorbers combined bearing seal and windage drag at 5000 RPM is only about 05 horsepower climbing to just 25 Hp at 10000 RPM. Just leave the engine at wide open throttle and go through the RPM range by adjusting the braking force. Smooth Quiet Control With E-Stop Capability The Positorq Oil Shear Absorber brakes are a unique design for continuous tension control The unique Oil Shear Technology provides extremely smooth ultra quick response negligible wear with no adjustment required high energy Brake Engagement.

VERY hard to find because they are made outside the US. An 8 pound absorber handles over 65 continuous Hp at 12000 RPM. A small footage of the basic principles of the water brake dyno used at standard tractorpull events.

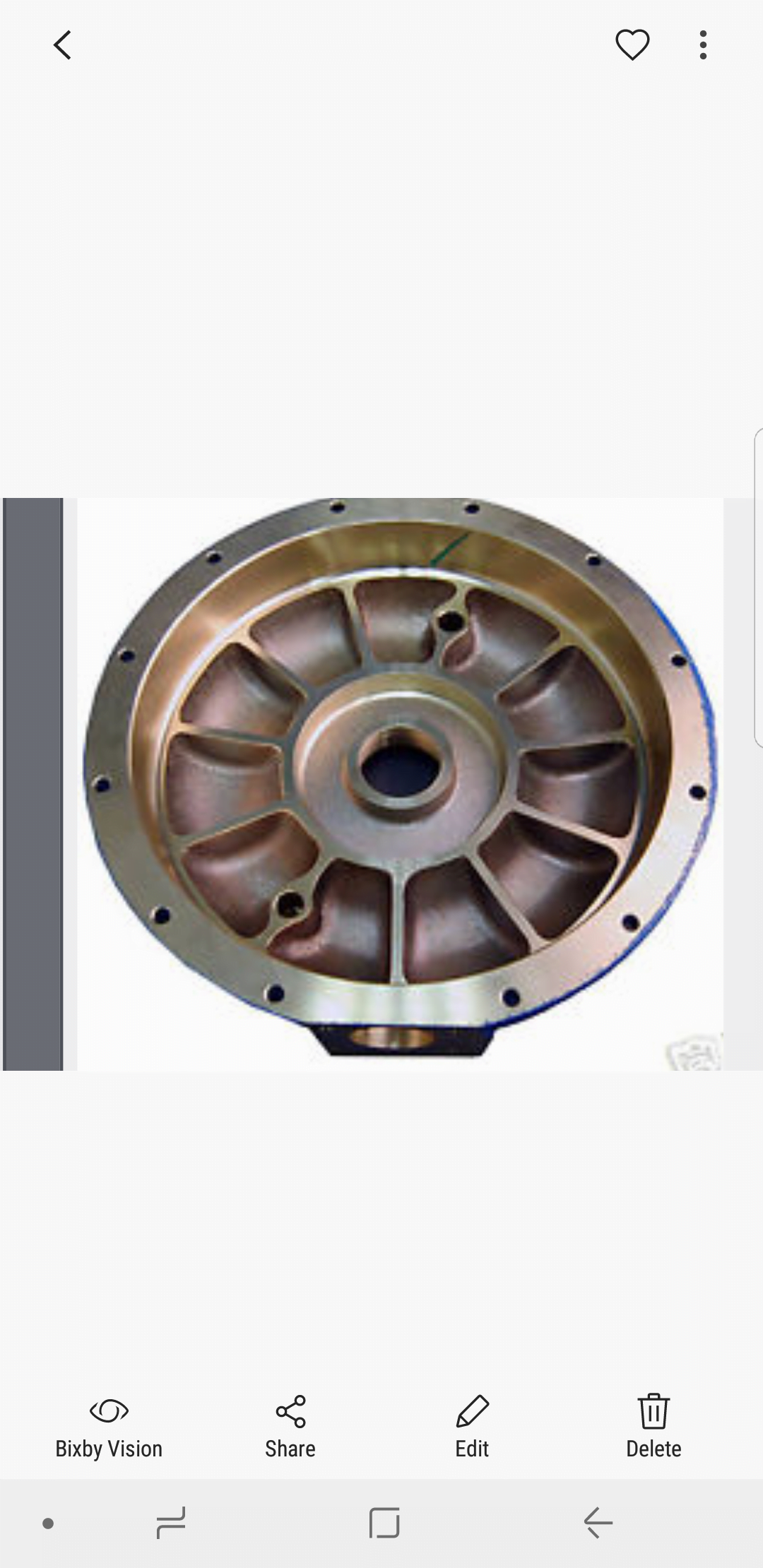

A water brake absorber consists of one or more shaft mounted rotors and at least two stators or end bells. A water brake is a type of fluid coupling used to absorb mechanical energy and usually consists of a turbine or propeller mounted in an enclosure filled with water. Water brakes A water brake.

There are 8 coils either side of the stator 16 in total. Choose from a full array of products built with heavy-duty components for proven uptime and longevity continuing a tradition of advancing. Power capacity versus size of a water brake is impressive.

Using water as the working fluid. Normally they are operated in 4 stages 2 coils either side for stage 1 4 coils either side for stage 2 so on. Full-bridge strain-gauge load cell.

Each side of the stator is supplied one fluid inlet and outlet totaling four inlets and outlets for the system. Rotor on shaft. For our absorber we will design for 42mm water in packing.

Deal with a challenge that is most popular in your concentrate on field then tie it straight to a solution you. The rotors spin freely inside the absorber housing in the absence of water. The paper investigates the effect of several design parameters of a dynamometer water absorber brake.

This type of absorber is widely used in dynamometer testing of various applications due to its relatively inexpensive and power-dense design. Water Brake Absorbers Water brake dynamometers use a hydraulic brake that converts the energy produced by the engine into heat transferred to the water flowing through the dynamometer. A big absorbtion dyno can be made of a bigger AC motor if one is handy.

A single absorber unit is made of two stators on either side of a rotor as seen in Fig. Brakeabsorber dynos works by braking the engine and measuring the force torque it takes to brake it over the RPM range. Since standard tractors are allowed to a certain amount.

This issue ought to make the viewer want to open up the brochure to learn more. An absorption unit absorber to absorb power through momentum exchange. Visit Our Website Today To Speak With An Expert About Your Dynamic Measurement Needs.

Thus A area of cross section G G. For the dyno i will wire all the coils together. In essence the fluid flow in the two designs are almost identical with the cupped design being more efficient.

Such applications include the bench testing of motorcycle automotive heavy equipment and even marine engines. Thus for 42mm of water m of packing height K 4 14 Fp 223 μ L viscosity of water at 45 0C 63 Cp G K4 v l - v 131 Fp μ L l 12 G 606 Kg m2sec.

Tech Talk Animation On How Water Brakes Work Youtube

Scratch Built Water Brake Questions Answers And Shared Experiences Yourdyno Com Forum

Scratch Built Water Brake Questions Answers And Shared Experiences Yourdyno Com Forum

Scratch Built Water Brake Questions Answers And Shared Experiences Yourdyno Com Forum

Figure 1 From Control Oriented Modeling Of A Water Brake Dynamometer Semantic Scholar

Land Sea Absorbers Water Brake Water Brake Absorbers

Pdf Design Development Of Dynamometer Water Absorber Semantic Scholar

0 comments

Post a Comment